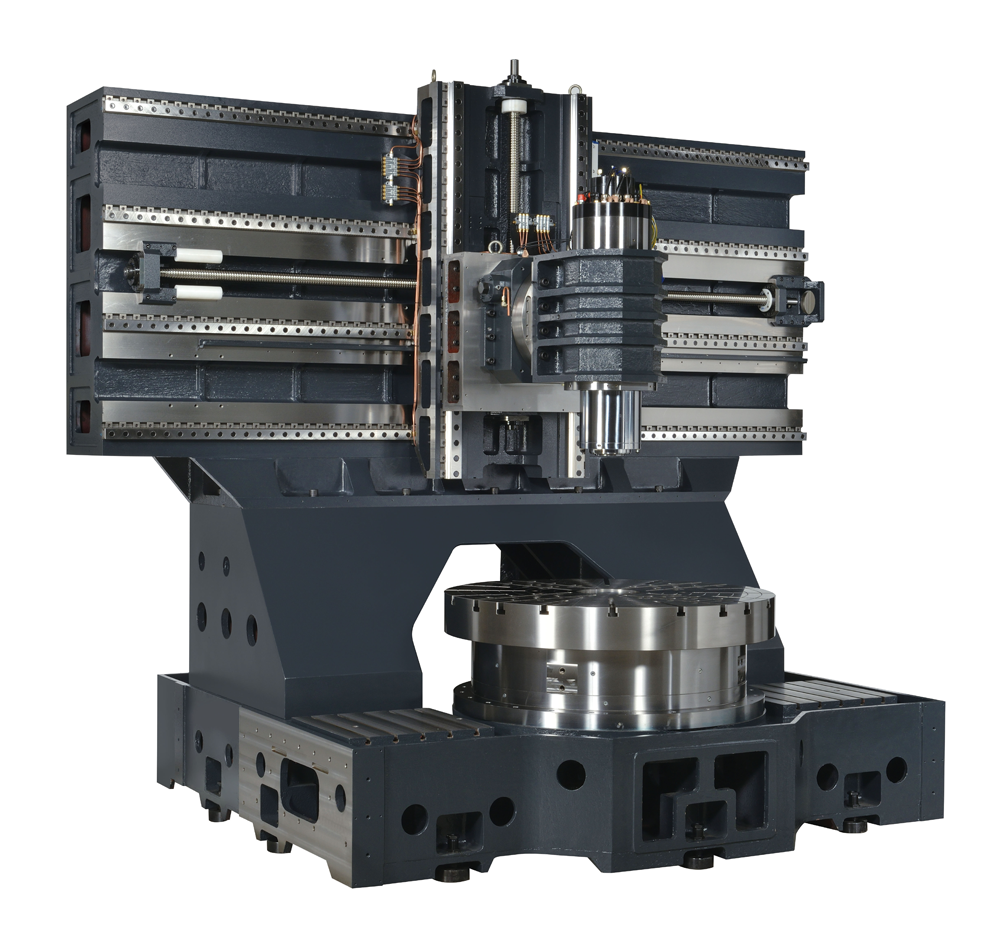

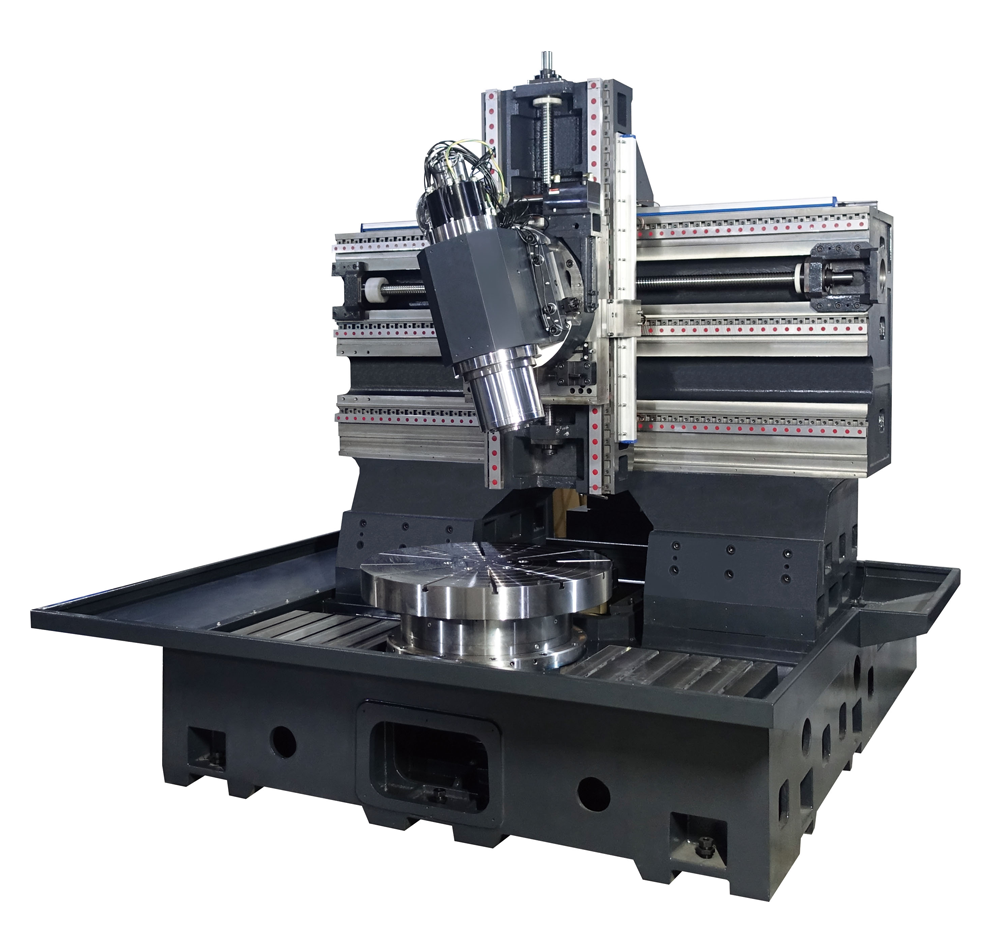

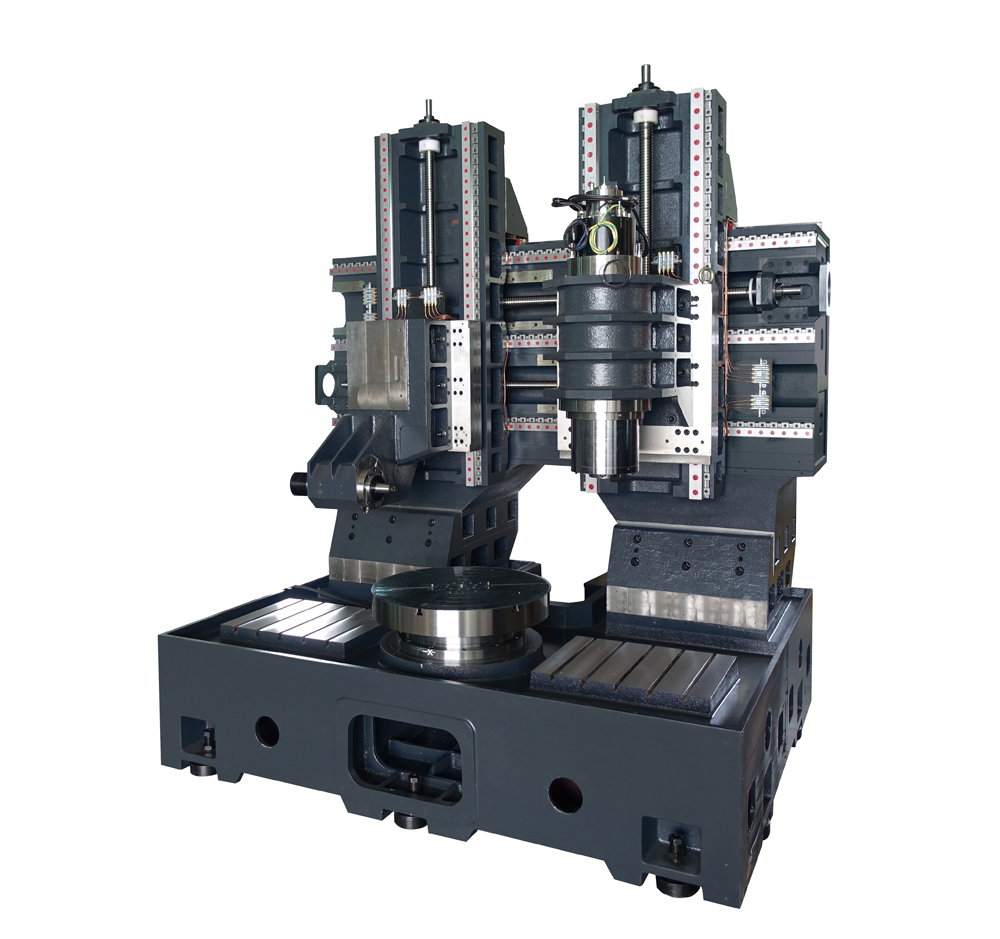

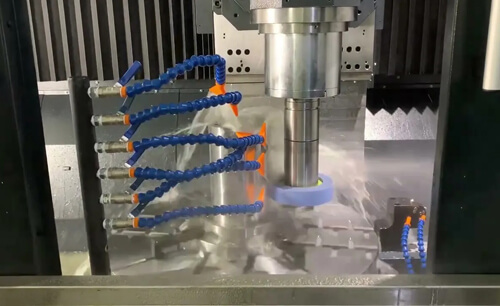

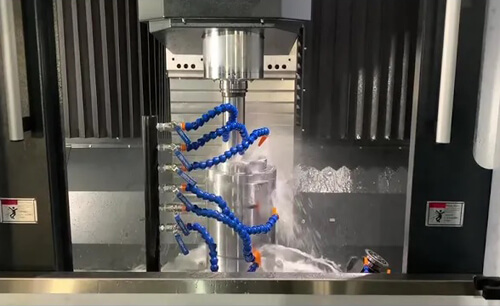

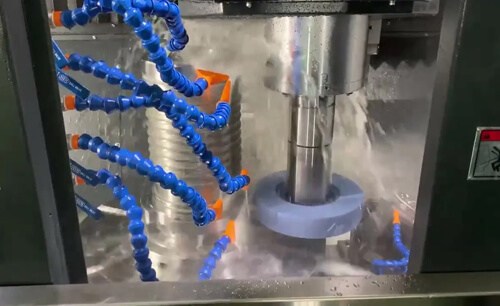

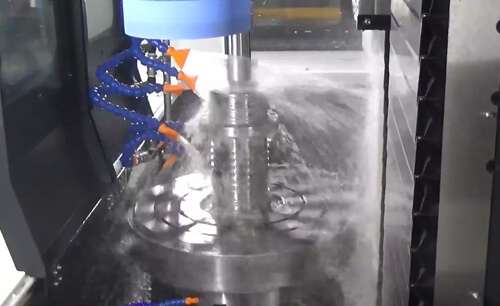

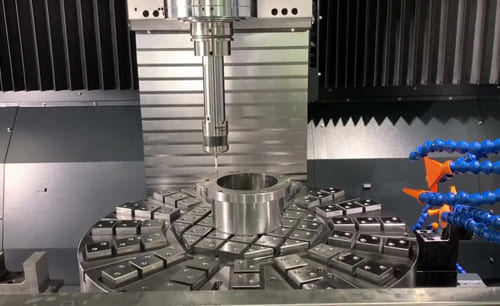

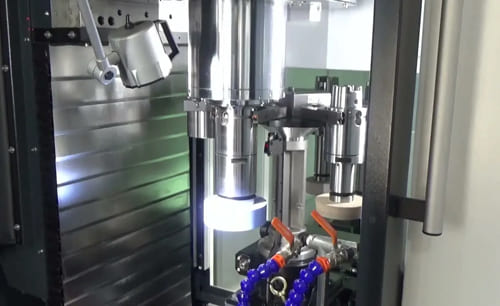

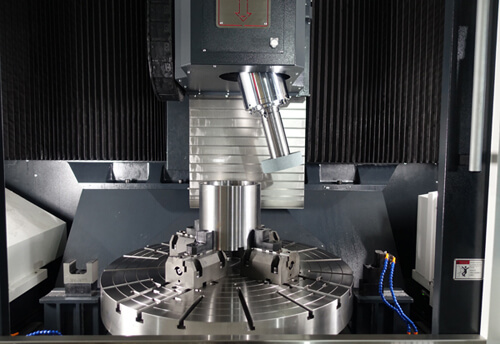

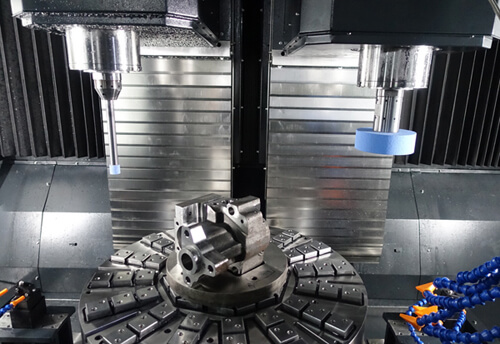

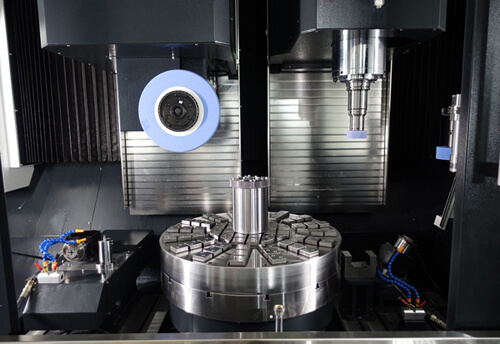

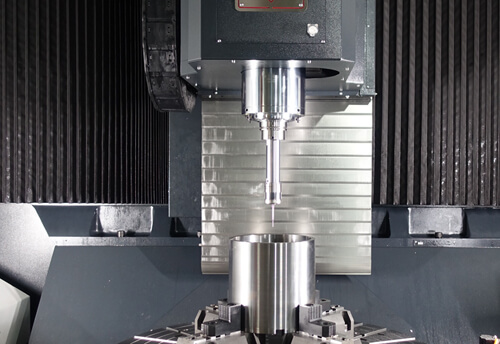

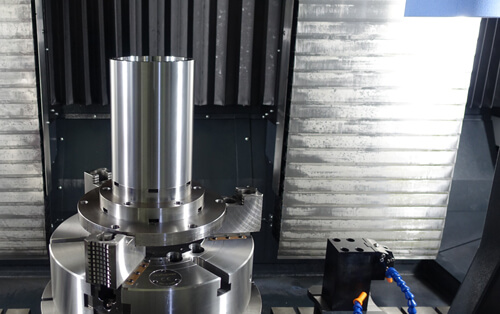

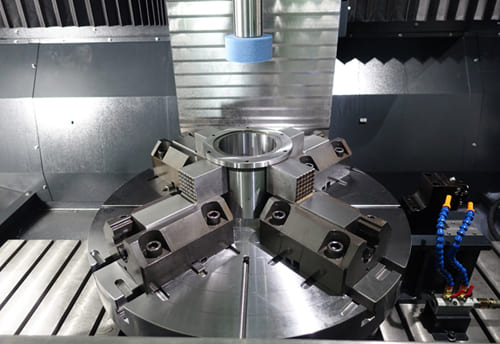

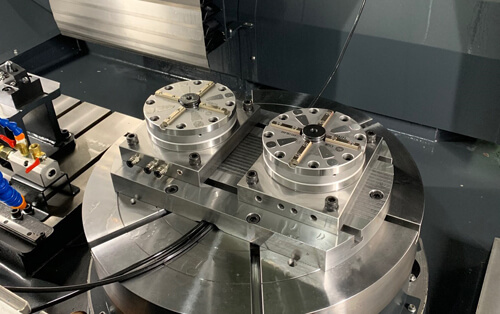

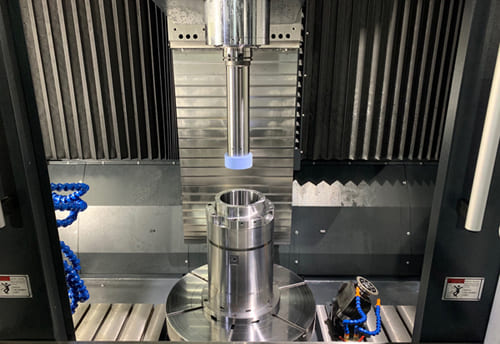

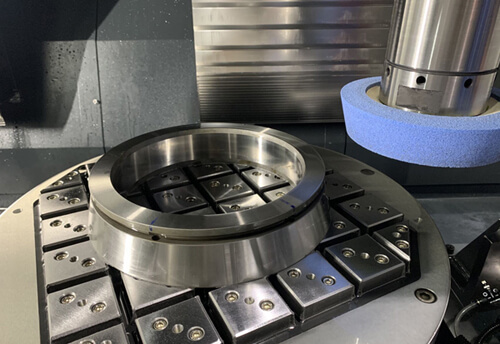

The vertical design provides high precision, high stability,small machine footprint, and heavy work pieces are not impacted by gravity when clamping.

Inquiry ProductVertical Cylindrical Grinder

All

Feature

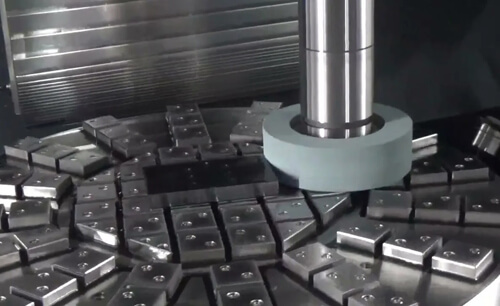

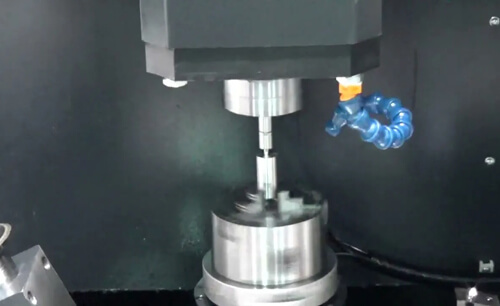

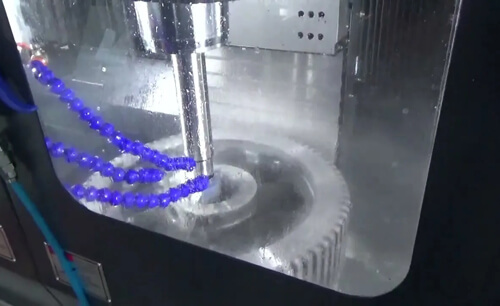

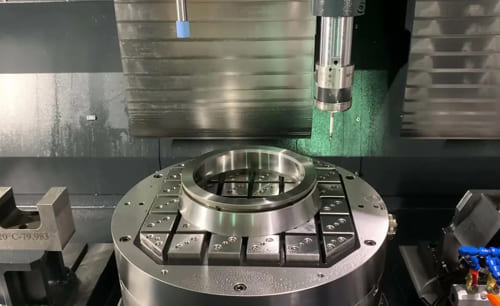

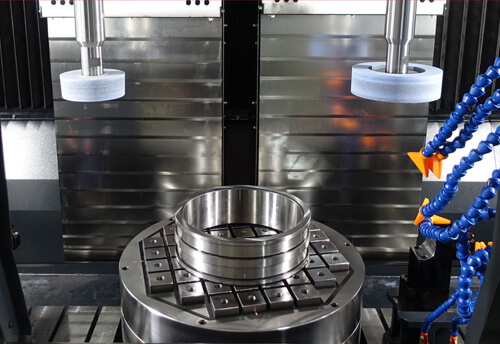

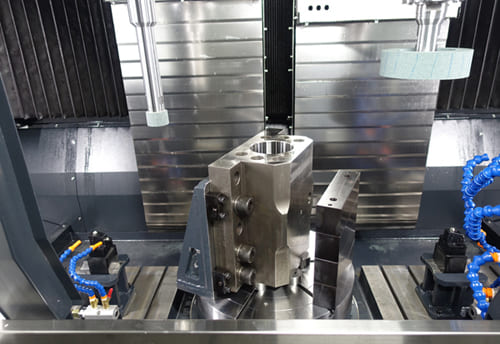

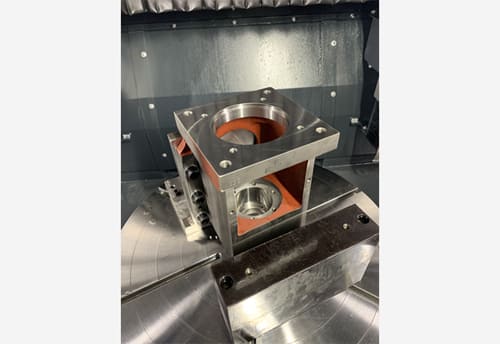

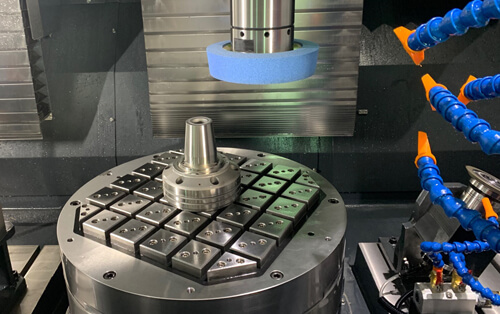

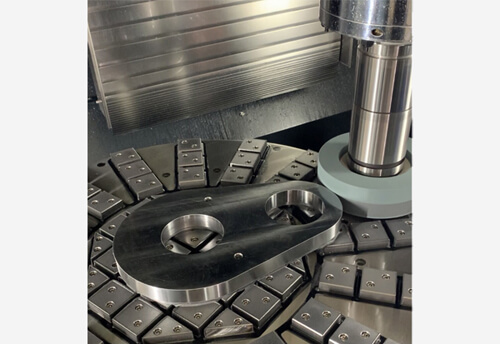

- Suitable for grinding inside and outside diameters as well as the end surface of heavy or non circular work pieces.

- Heavier work pieces can be more easily loaded to the machineby overhead hoist.

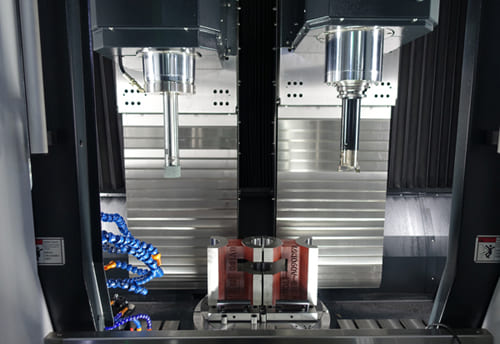

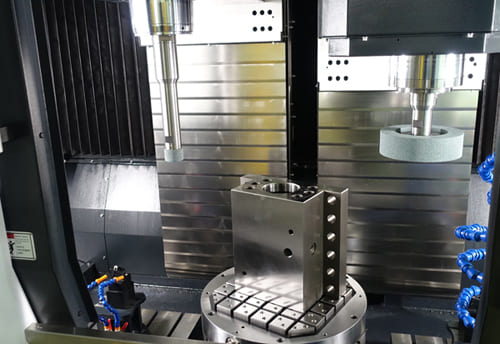

- Double column designed structure provides better machine stiffness.

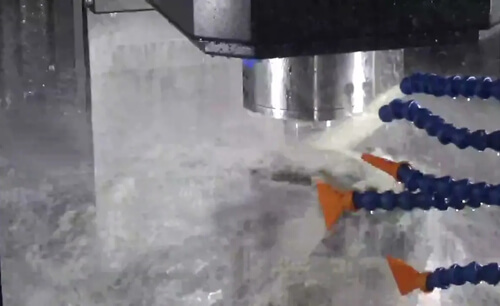

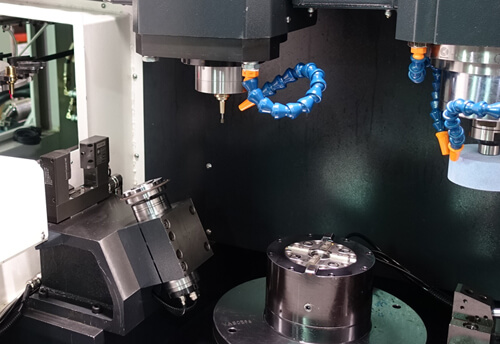

- Fully enclosed covers and oil mist reclaiming device prevent leakage of grinding oil and mist.

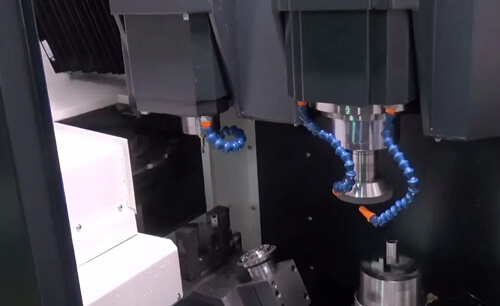

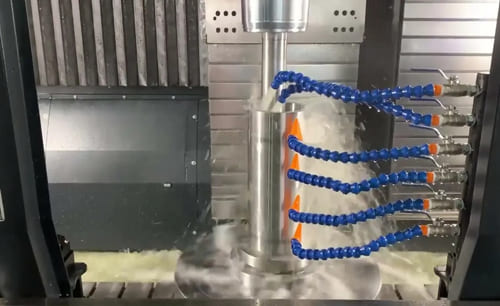

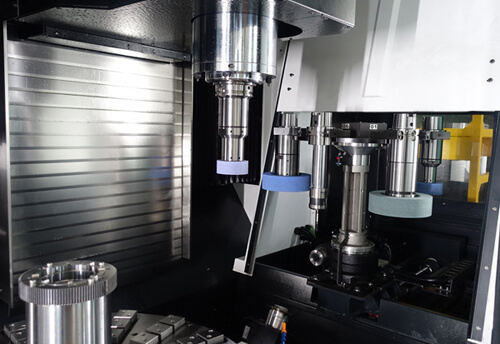

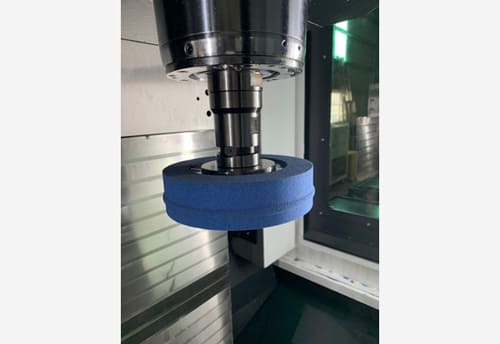

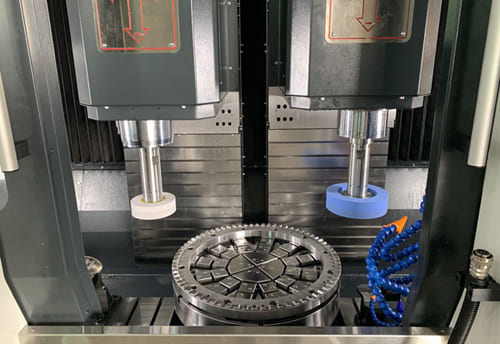

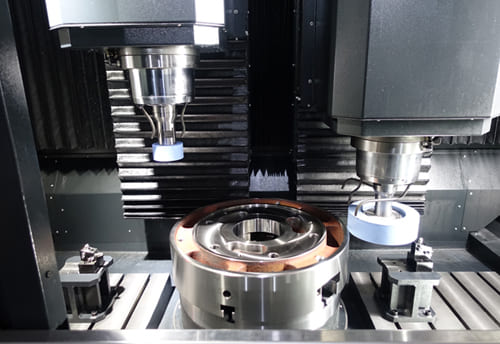

- Options of SINGLE-spindle or DOUBLE-spindle, with or without tool changer.

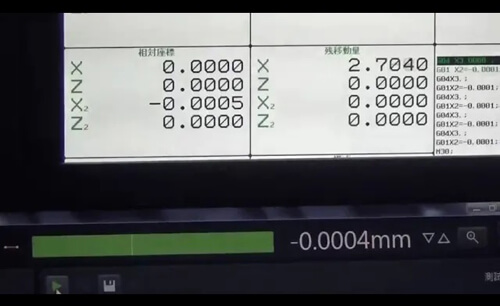

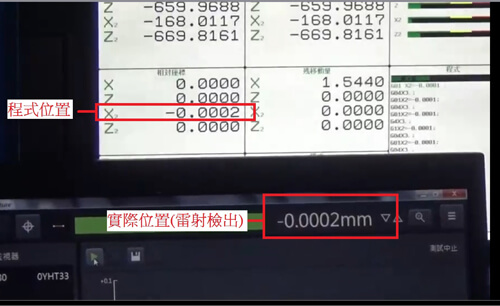

- Fanuc controller plus 10" screen man-machine touch panel.

- Conversational programming function makes the control operation and program creation easier to understand.

- Double-spindle model can be equipped with grinding wheels for both high and low RPM’s, also, both large and small grinding wheels can be used.

Specification

*Note: (1)The spindle type can be customized. (2)Mechanical opening height: Maximum distancefrom spindle nose to table. (3)Spindle RPM, Power, and Grinding Wheel Adaptor could be Customized.

Standard Accessories

- Oil mist reclaiming device

- Paper type filter

- Magnetic separator

- 3 x outer diameter handles

- Diamond dresser pens

- Table groove

- Tool box

Optional Accessories

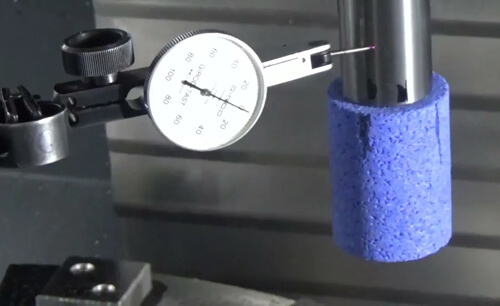

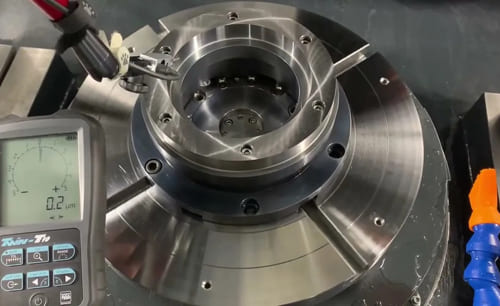

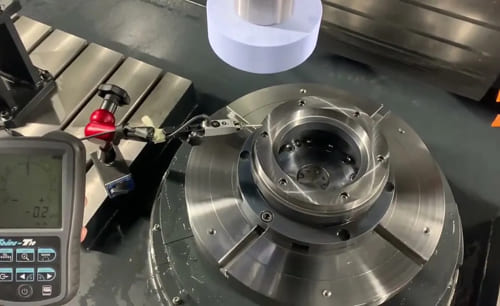

- Online detection

- Automatic gate device

- Electromagnetic chuck

- Power Chucks

- Power diamond dresser

- Collision avoidance detection

- Spindle monitoring

Video

Structure of Machine